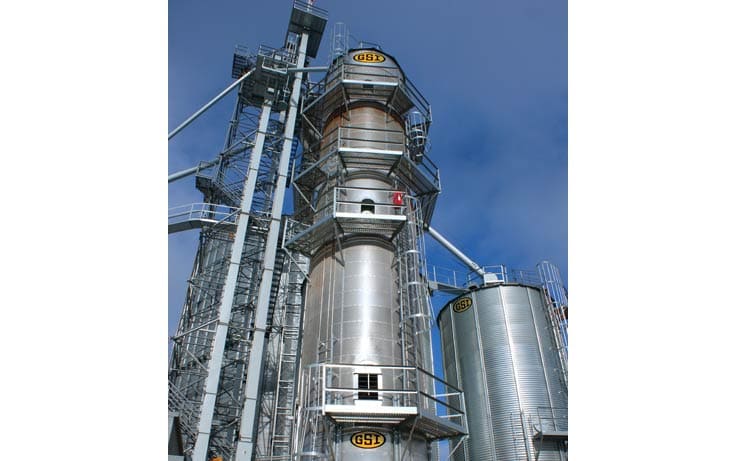

T Series Description

- Gravitational entrance decreases the number of moving pieces therefore it does not require drill grading.

- The self-cleaning padding box on the plenum roof reduces the damages on the grain and compression roof abrasion.

- Foil outside the stainless steel prolongs the drying life. As the screens use different dimensions, they reduce the emission level.

- 12-3/4″ grain columns surrounding the heat compression chamber reduce the noise and increase the efficiency, while the burner ensures that you obtain full BTU.

- Floor area is the least with an extra hard structure and heavy general construction results.

- Uniform low speed increases the hot air while the efficiency and quality reduces the particle emission.

- Safety stairs both inside and outside, cages and podiums ensure safe and easy access in all areas for drying.

- Patented Grain Transformers are used to increase quality and efficiency for the majority, and they are used to equalize column humidity contents and the temperature of the grain column.

- In-line Maxon NP-LE-AL series burners ensure heat and efficient burning even with natural gas or LP steam. Aluminum extrusion burners reduce maintenance requirements.

- Reduction cone ensures equalization of the burners that exceed the air speed for optimum burning and assembly access of the burner.

- Walk-in heat section provides easy access for internal cleaning.

- Divider chamber separates heating and

- While preventing it, the cooling sections build-up particle substances.

- The grains surrounding form a natural sound barrier and the internal assembly ensures ultra quiet operation.

- Internally assembled tubular centrifugal ventilators provide pressure, heat and section as well as higher volume air flow to cool sections.

- Significant fuel saving, cooling grain results, heat recycling.

- Walk-in cool section provides easy access to the measurement system.

- Patented discharging system provides simple, homogeneous measurement and fast drying and cleaning.

- (Maxon valves and burners etc) industrial quality components provide reliable services.

- Impermeable NEMA IV chambers and NEMA electrical components ensure safe and secure operation under all conditions.

Wide burner

1500 BPH and higher capacities. Maxon fuel saving, standard burner, equal distribution with special profile ensures constant heating.

Efficient, Quiet, Reliable and Developed Drying System

T-Series Tower Dryers have been designed in consideration of medium and large-scale enterprises. The capacities range between 1200 BPH and 2400 BPH.

During the cooling of the grain, all of the heat is regained and long preservation periods ensure an extra efficient dryer use. As a result of the conic chamber, particle accumulation at the heating section is prevented and this facilitates maintenance.

Self-controlling feature monitors the grain’s humidity and temperature meticulously. If you are looking for a quiet and reliable drying system, GSI T-Series Tower Dryers have all the features that would meet your expectations.

Small Burner

For 1200 BPH and smaller capacities, fuel saving standard octagon burner ensures homogeneously distributed constant heating.

Discharging with a broom system

Site tested (patented) self-cleaning Accutrol discharging systems allow for a positive grain flow from the columns.

Interior Roof

Heavy galvanized interior roof and supports provide storage for wet goods above 300 Bu. This section is isolated for preserving particulate materials.

Platforms

Developed interior and exterior (OSHA type) platforms, stairs and safety cages are standard features and provide easy access to the tower drier.

Access Doors and Caps

All of the sections of the drier are equipped with doors and caps for cleaning and maintenance purposes.

Grain Transformer

Patented grain transforms balance the column humidity content and grain column temperature. (This is a standard feature in T-1575 and larger dryers. Optional in T-1050 and T-1260 dryers.)

Vision Network Control System

GSI Vision Control System allows controlling the entire drying functions from a single point with a touch screen that can be easily used. System is windows ce.net operating system and 32-bit microprocessor is used. Automatic humidity control is integrated to the dryer’s main controls and among its features, adjustable sample taking periods, obtaining graphics and providing time markers can be listed. Some of the important features of vision controls include the lack of moving parts, all of the dryers and the main electrical safety switches are equipped with low voltage control circuits and connecting control box with less than five cables.

New Industrial Fans

Highly efficient, quiet, industrial type fans are used with 1500 BPH and larger dryers and they work for years without any faults.

Hot Air Chambers

The hot air chamber is completely surrounded with 32 cm grain column. All of the hot air passes through the grain column and ensures that the entire hot air is used. Stainless steel, 0,20 cm and 0.15 cm diameter wrought iron, straight lateral walls allow for the preservation of the maximum amount of particles.

|

Model

|

T-1050

|

T-1260

|

T-1575

|

T-1875

|

T-20100

|

T-24100

|

|

|

43″ Axial |

43″ Axial

|

8490

|

8542

|

8542

|

8600

|

|

|

1750

|

1750

|

1035

|

856

|

981

|

818

|

|

|

50

|

60

|

75

|

75

|

100

|

100

|

|

|

1

|

1

|

1

|

1

|

1

|

1

|

|

|

42.300

|

48.400

|

77.100

|

81.800

|

98.600

|

108.300

|

|

|

14.500

|

17.500

|

38.500

|

40.900

|

49.300

|

54.150

|

|

|

11.100

|

11.100

|

16.654

|

17.669

|

21.298

|

23.393

|

|

|

5.711

|

6.534

|

10.409

|

11.043

|

13.331

|

14.621

|

|

|

32 cm

|

32 cm

|

32 cm

|

32 cm

|

32 cm

|

32 cm

|

|

|

3.65 m

|

3.65 m

|

3.65 m

|

3.65 m

|

3.65 m

|

3.65 m

|

|

|

13.9 m

|

15.95 m

|

17.98 m

|

21 m

|

23.06

|

26.11 m

|

|

|

7.5 ton

|

7.5 ton

|

7.5 ton

|

7.5 ton

|

7.5 ton

|

7.5 ton

|

|

|

15.2 ton

|

18.9 ton

|

22.8 ton

|

28.9 ton

|

31.4 ton

|

37.4 ton

|

|

|

5.5 ton

|

6.7 ton

|

7.6 ton

|

8.8 ton

|

11 ton

|

12.5 ton

|

|

|

30.8 ton

|

35.6 ton

|

40.5 ton

|

47.8 ton

|

52.7 ton

|

62.5 ton

|

|

|

25 ton

|

30 ton

|

37.5 ton

|

45 ton

|

50 ton

|

60 ton

|

|

|

15 ton

|

18 ton

|

22.5 ton

|

27 ton

|

30 ton

|

36 ton

|

Discharge Adjusting Engine

SCR impulse, geared DC engine and Cyclo gearbox that does not require maintenance, are located within the cooling chamber. They ensure that the discharging system works easily and without any problems.

Standard fans and Conic Section

Efficient, quiet, adjustable pitch Fan ensure high levels of airflow with low horsepower in those dryers that are 1200 BPH and smaller. Cone shaped chamber around it prevents the accumulation of particles in the heating center of the dryer.