Right Silo for the Right Job,

These series have been designed for the modern grain producers and distributors of today. GSI conic base grain storage silos provide safe and beneficial services for long years. GSI offers the most accurate solutions with the right silo systems in relation to wet or dry grain storage, mixed silos, long term storage and over ground discharge system requirements.

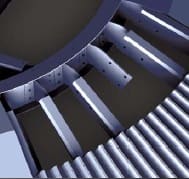

Strong support legs above the ground;

GSI conic base storage silos start at the concrete base with the extra strong “wide flange” legs that are welded to thick steel base plates at the factory. The legs are cleaned, they are custom prepared and they are dyed so that they can be more durable. The durable brace clamps that are found in the upper sections of each leg and other lock connecting pieces that combine the legs ensure that the conic part and the silo body are bolted to each other as a single unit.

Silo legs are even further reinforced depending on the dimensions of the silo, the product that is being stores and specific seismic and wind conditions, with custom designed, “X” shaped supporting pieces or long bars that have high standard tension strength or by using steel supports that are extra strong structurally.

Endurance of the conic part… First Task!

In conic base silos, the endurance of the conic part is particularly significant in relation to the expected life of the entire silo. For this reason, each conic panel is sensitively manufactured from highly durable, commercially galvanized steel and they are designed in such a way that they can provide maximum support once assembled.

Conic panels are manufactured in diverse proclivities depending on their purpose of utilization and silo measurements. 40-45 degree conic angle silos are usually suitable for dry or wet products that have well fluidity levels. 60-67 degree conic angle silos on the other hand are used for products that have worse fluidity levels.

Adjustable flow gates

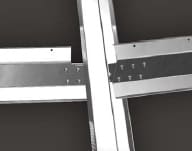

GSI manufactures two types of commercial conic base silos. These include the strong NCHT Series, which have 2,66” (66,7mm) corrugation distance on lateral wall plates and FCHT Series, which have a wider corrugation distance, 4” (101,6 mm). Within the NCHT Series, there are different options that can address all kinds of conic base silo requirements with different diameters (15 ft-36 ft/ 4,57 m-10,97 m), capacities and 40-45-60 degree proclivities. FCHT series only provides 45-degree proclivity option. It has been designed for more special, intermediary capacity intervals, with a strong and reliable design and for limited dimension/capacities and provides price advantage as well.

Easily accessible, 60 cm diameter silo entrance doors are contained within the second ring in GSI commercial conic base silos as a standard feature. They are completely welded onto the round lateral wall sheet and they are cold galvanized. This way the strongest and long-lasting product can be obtained. Non-permeable interior door panel is easily locked with a sliding double clamp system.