- EACs remove lightweight products and separate broken kernels and large-size waste from the good grain.

- These operations are carried out by double-acting suction followed by a rotating drum.

- The raw product is spread out in a uniform layer and a current of air blows through it.

- The proportion of lightweight products driven off is altered by adjusting the suction power.

- The heaviest particles settle in the holding chamber and are extracted by a screw.

- Lightweight particles are expelled (V) by suction. A direct output P enables the work to be stopped there if desired.

- The grain then flows into a rotating drum with interchangeable grids.

- The first of these remove broken kernels and those following let the good grain pass through.

- The largest elements exit from the bottom of the drum.

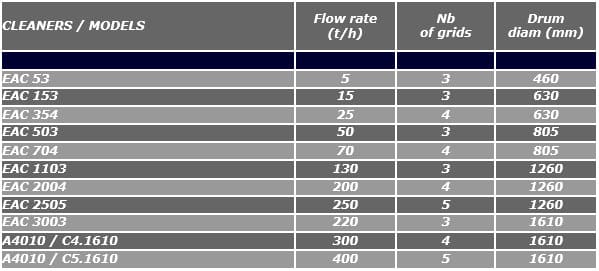

- The succession of grids with different perforations make these devices remarkably useful for all types of grain, at low rates from 5 to 400 tonnes/hour.